Dairy tech moves from the lab to industry

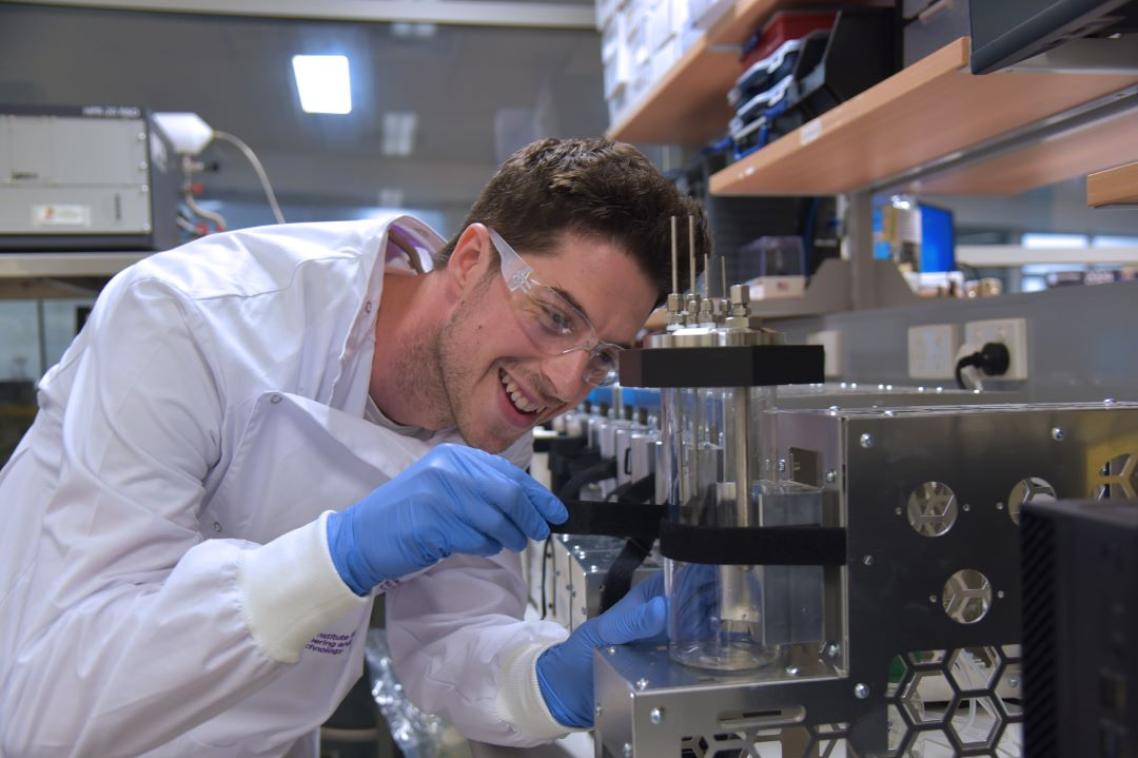

Dr Aiden Beauglehole working with the UQ bioreactors.

Dairy products made using precision fermentation are a step closer with Australia’s Food and Beverage Accelerator transferring new technology to an industry partner.

A team, led by Professor Esteban Marcellin at The University of Queensland, has produced dairy proteins in FaBA’s research bioreactors and Sydney-based company All G is scaling up the process to develop a milk supplement.

“We followed the same process as the fermentation of beer but instead of making ethanol, we have produced dairy proteins,” Professor Marcellin said.

“Through precision fermentation, we have created proteins for people with specific dietary preferences.

“A key part of the project was to transfer new technologies, such as the new bioprocess, from the lab to a company, and this will speed the path to commercial outcomes for All G.”

UQ Senior Scientific Officer Dr Aidan Beauglehole has worked closely with the All G team to develop a specific fermentation process relevant to their business.

“FaBA’s custom-built bioreactors allow us to carefully manage every element of precision fermentation,” Dr Beauglehole said.

“We can precisely control oxygen uptake in the system, control pH at exact levels and we have tested different conditions to ensure optimal growth.

“By closely monitoring and adjusting every element of the fermentation, we have demonstrated we can improve growth rates and better control any by-products of the process.”

Transferring the technology from FaBA’s small bioreactors in a laboratory setting to All G’s bioreactors in a manufacturing environment involved scaling the various elements of fermentation to ensure suitability for the larger production units.

“It is very exciting that FaBA’s Innovative Ingredients Program has transferred this technology to an industry partner,” said Dr Beauglehole.

All G Chief Technology Officer Dr Guillaume Barbier said the optimised bioprocess would allow the start-up to expedite its development of dairy products.

“Precision fermentation is an emerging yet crucial industry for the future of dairy products,” Dr Barbier said.

“Working with FaBA has allowed us to move ahead of the curve with the development of dairy products using new technology good for people and the planet.”

Collaboration and acknowledgements

The project was supported by the Australian Government Department of Education through the Trailblazer Universities Program.Related articles

Superconducting germanium made with industry-compatible methods

Peptides to prime plant defence against viruses in vegetables

Media contact

FaBA Communications, Anna Moloney

a.moloney@uq.edu.au

+61 478 487 211